Development of a system for the validation of industrial parts pose on conveyor belts with a focus on simulation and advanced experimentation (Master's Thesis)

15 feb. 2024

Description:

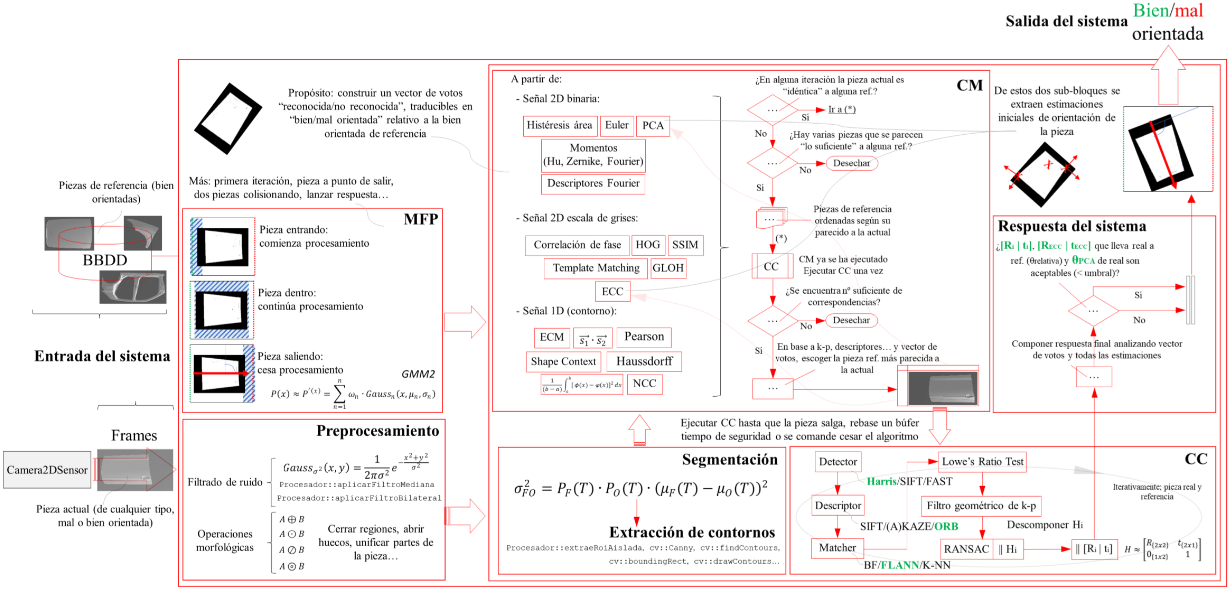

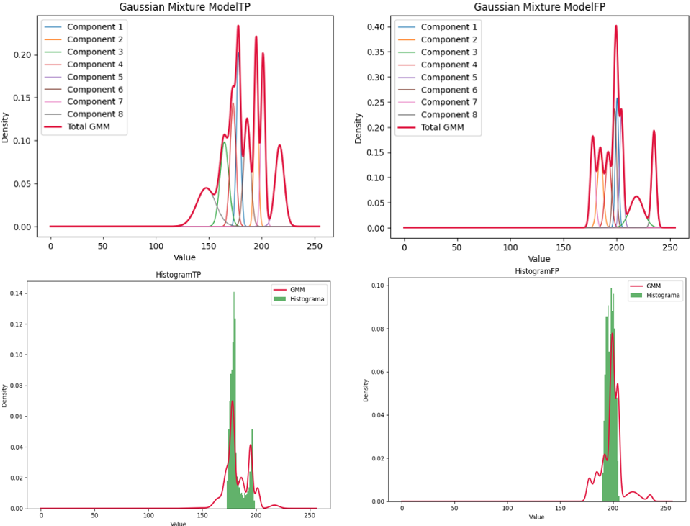

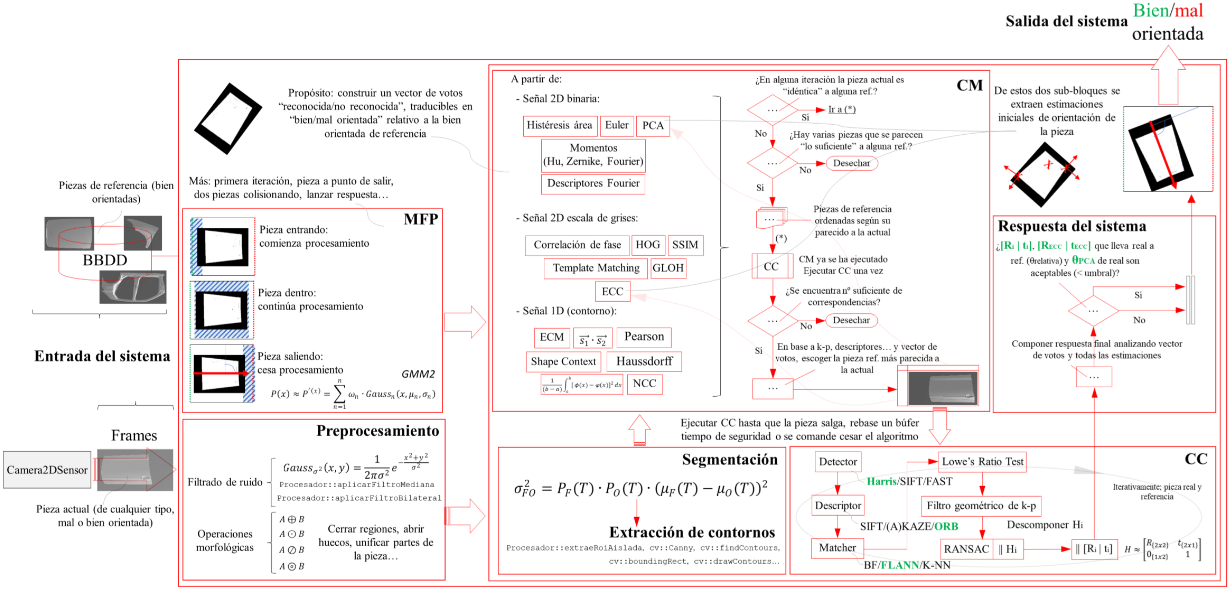

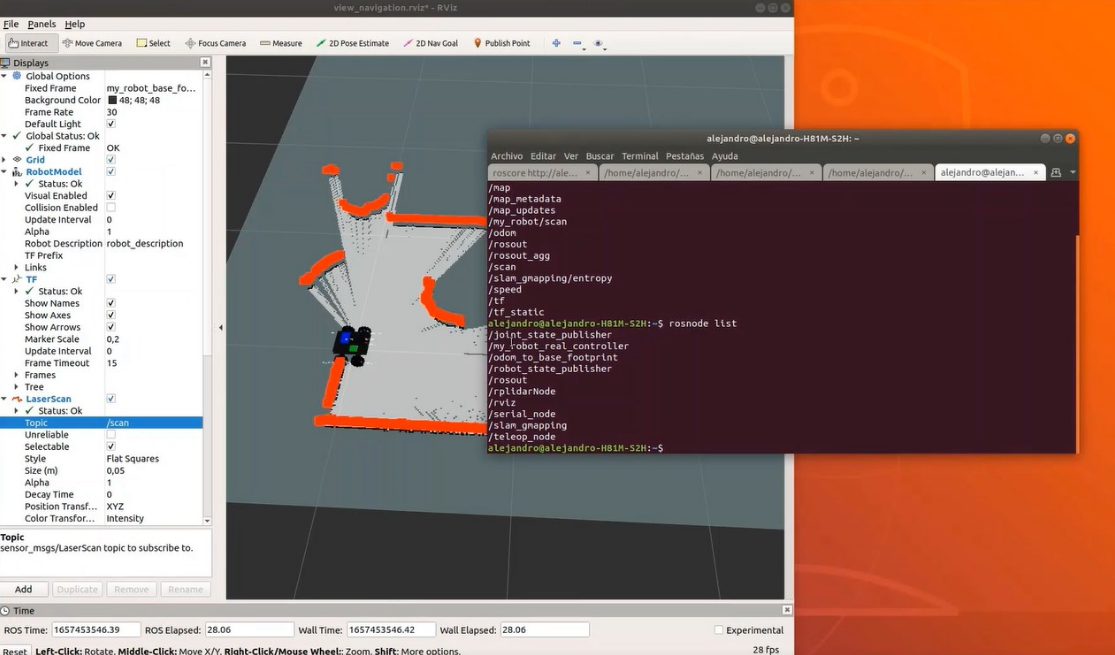

This project focuses on developing a system that uses reference and current images from a 2D camera to monitor and analyze parts on a conveyor belt in an industrial environment. Graphical user interfaces, communication interfaces, and software are implemented for integrating sensor data, running preprocessing algorithms, motion detection, feature extraction and comparison, as well as object recognition using classical computer vision techniques. A practical solution is proposed, developed under the Qt framework, supported by a robust simulator that facilitates the experimentation and refinement of algorithms in simulated 3D industrial environments. The simulator is presented as a versatile tool that can support the research of various computer vision and machine learning techniques; developed using the OpenGL standard and the C++ programming language with an object-oriented approach, it serves as a powerful and versatile tool for 3D emulation of industrial spaces. The implemented algorithm, using the OpenCV library, acts as an analytical classifier to determine the validity of a part's pose on a production line. Two data sources are used: a static collection of images (reference parts) and pre-calculated feature vectors, and on the other hand, frames from a 2D camera (parts to be validated). The system employs quasi-intelligent algorithmic entities to process images and other signals, perform numerical analysis, feature recognition, and other tasks, generating a final response based on quantitative estimates, votes, weightings, and empirical thresholds. The combination of multiple algorithms proves effective in handling variations and complex deformations. An experimental phase is highlighted, both in simulation and reality, where various environments and conditions are set up to measure the system’s ability to classify valid and invalid parts, as well as its accuracy in adverse scenarios. Finally, after testing the system using statistical repeatability analysis to evaluate its robustness under various cases, the results are analyzed, and it is concluded that the system as a whole, along with the implemented algorithms, proves effective, culminating in a comprehensive solution that successfully addresses the challenge of monitoring and analyzing the pose of parts on a production line.